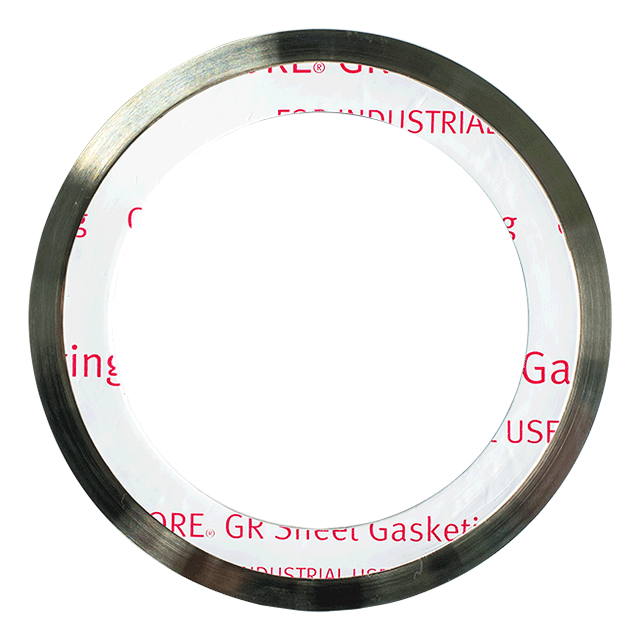

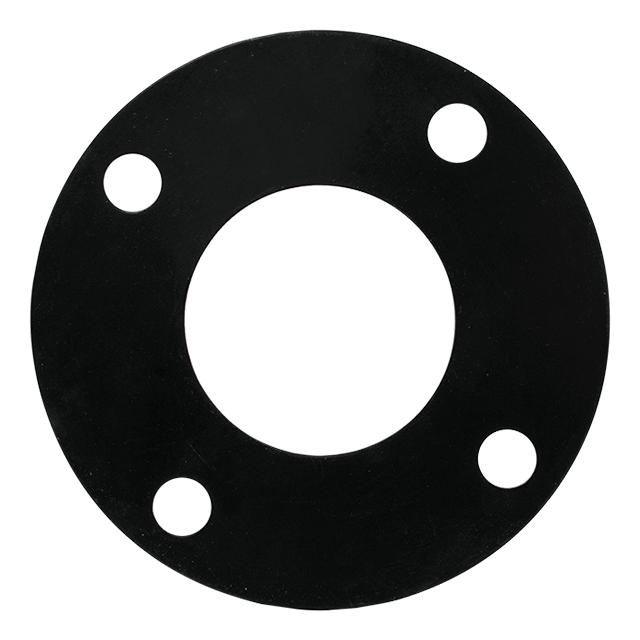

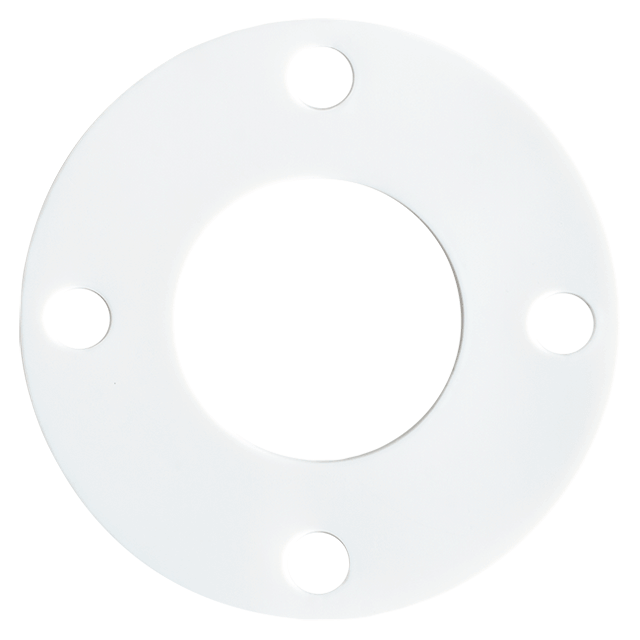

Joint Sealant is a sealing solution for steel flanges with large diameters, rectangular or irregular shapes, and rough or pitted surfaces. When compressed, this soft, conformable cord forms a thin yet strong seal. It can also seal applications where available bolt loads are low.

Joint Sealant is standard sealing material for many MRO (Maintenance, Repair and Operations) teams because it seals reliably – and because it’s easy and cost-effective to install. For most applications, just peel off the adhesive backing, apply to the surface, and overlap the ends.