Valve Maintenance Services

“Our MPAC Pump & Valve success story has begun in 2010”

Since 2001, Masterpac-Asia is a major manufacturer and supplier of flow and sealing products for demanding applications throughout various industries by providing premium quality gaskets. Our move into valve maintenance services in 2010 as named “MPAC Pump & Valve” is a step we feel is necessary to try to cut emissions and make Thailand a cleaner place to live in. Customers who have come to know MPAC Pump & Valve well, understand that whatever pump & valve related problem or project they have, we can take care of it and do so to an exceptional standard.

“Any Job, no matter how complex or how large”

Refurbishing pumps or valves is the main stay of MPAC Pump & Valve. By having our own in-house equipments and blasting units, we are specialists in overhaul of control valves and the refurbishment of hand valves, safety valves and every other type of industrial valve you can think of.

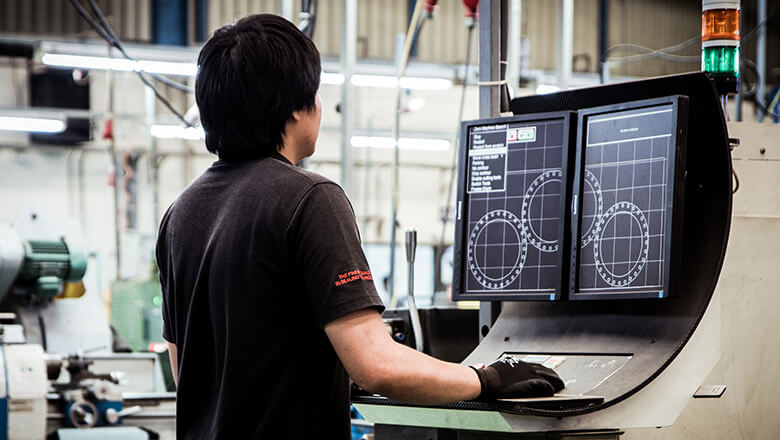

“Technology is an integral part of our success”

Our valve testing and valve repair are done on a state-of-the-art testing machine being the only one of its type in Thailand. Having twin test beds, it has a capacity to test any type of valves up to 400 NB (16") valve giving a PLC report on the test showing pressure curves and in the case of safety valves crack pressures during testing. For Lapping System, MPAC Pump & Valve employs the V-TEC system with a range from 1½” – 40” which has the capacity to cover the most valves in industry.

“24/7 rapid breakdown service”

Moreover, MPAC Pump & Valve offers a 24/7 breakdown service to rapidly attend the unexpected, especially when a valve failure results in loss of production. Our experienced pump & valve engineers and technicians will get there fast and fully equipped with the latest technology tools to quickly analyze the problem and prescribe the solution.

“Expertise in shutdowns and turnarounds”

Participation in planned shutdowns and turnarounds is another key aspect of MPAC Pump & Valve's business for which we are widely known and respected. We offer a comprehensive package of on-site services to ensure efficient, reliable plant operations. This service embraces emergency repair, maintenance and repair contracts and the installation of new plant and equipment.

“Truly one stop service for valve repair”

MPAC Pump & Valve is supported by Masterpac-Asia, the leader in sealing technology, so we always choose the most suitable sealing products e.g. gland packing or molded graphite rings for each applications within the timeline and being truly one stop service for valve repair. We also be able to provide additional service, by having epoxy coatings for both the interior and exterior of the pumps and valves in order to increase the longevity of the components in service.

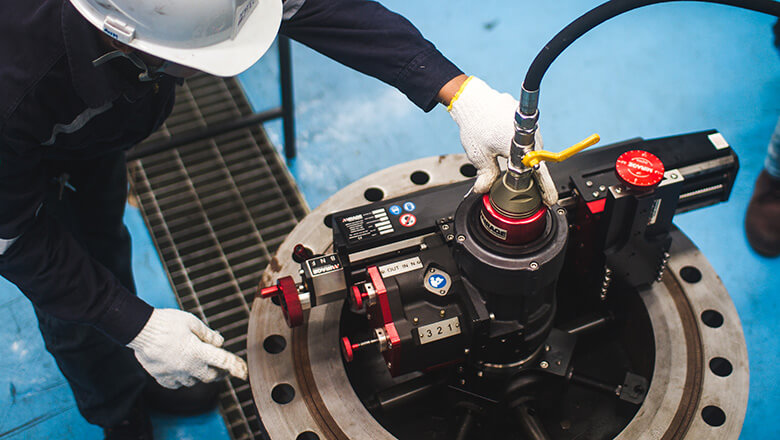

Bolt Torque Services

Masterpac offers first-class on-site hydraulic bolt tightening services. From a simple bolt-up of a single flange connection down to maintenance and major-shutdown site services, we utilize only the best equipment and tools and employ only the most experienced engineers available in the industry.

All Masterpac torque equipments are tested and supplied with applicable test or calibration certificates. We offer hydraulic torque tools with both air and electricity-driven power packs which can be used within hazardous environments such as off-shore platforms, eliminating the need to shut down.

Flange Facing Services

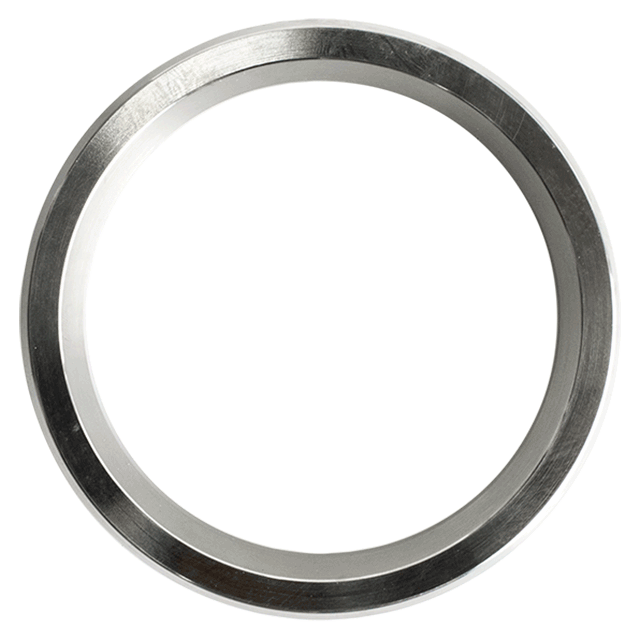

Flange facing is a process of machining the faces of flanged and other types of pipe and vessel connectors. It is used to repair faces either damaged from impacts with other components during construction or installation or from corrosion and erosion due to turbulent flow or cuts from gasket leaks. Also included in the process of flange facing is the machining of hub profiles, the front and rear faces of heat exchangers, oval manways, oval handholds and sealing surfaces of pressure vessels and boilers is possible. Grinding and polishing attachments are also available. At Masterpac, we can machine most any size and type of flange from raised face to ring joints. We have OD and ID mount equipment so no matter the flange we can machine it in place, and all work is done to industry standards and specifications.

Technical Support

Masterpac products are supported by a range of services which are designed to offer complete solutions to our value customers. This service offering ensures that we are able to develop innovative solutions for the world toughest sealing challenges, meet the requirements for rapid response during plant shutdowns and provide the necessary knowledge and competence to fit our products safely.

Ranging from problem solving, on-site measurement, to product redesign, our Application Engineering, Production Engineering, R&D and QC teams work closely together to design, develop and select the best products and services to meet the challenges faced by each industry. Our experienced teams have a wide range of expertise in different industries and applications which will enable our customers to significantly reduce operating costs, increase reliability, and realize years of trouble-free service.

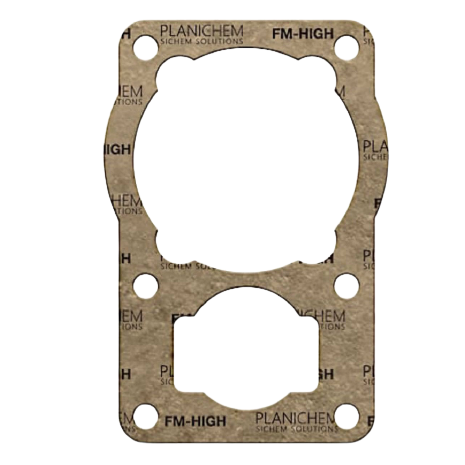

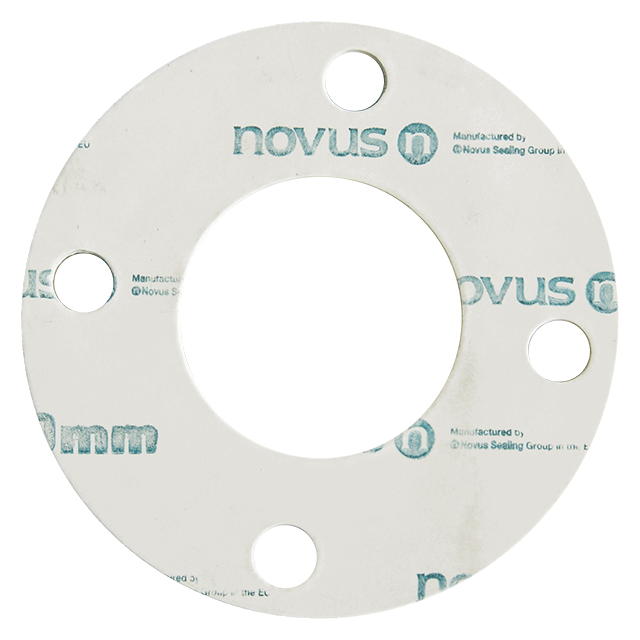

Gaskets Custom Cutting

Masterpac offers the latest technology in computerised gasket cutting. We have a complete gasket cutting service for virtually any shape, size or material, using the ATOM and Aristo CNC programmable gasket cutting machine that is capable of producing gaskets to exacting tolerances, to any size and shape, within a very short lead time. Gaskets can be produced from samples, drawings or templates. The data is then recorded for future orders and the identical gasket can be repeated to the same specifications time after time.

Moreover, we also offer laser cutting which has the capacity to cut Stainless Steel, Carbon Steel, Aluminium, Titanium and many other alloys and materials. Doing both in house work and jobbing work for local industry, this machine is truely the heart of Masterpac 24/7 service to industry.

PMI Testing

Positive material identification (PMI) is an essential non-destructive testing (NDT) method utilized to verify that supplied materials conform to the proper standards and specifications. As a result, assurance can be gained that the chemical makeup of the metallic parts has the correct percentage of key elements. Masterpac offers PMI testing services through experienced, trained personnel who can assure quality of service. The material scan and testing services can be performed on-site before the pieces go into the production process. At Masterpac, we use a Thermo Scientific Niton XL2 Series x-ray fluorescence (XRF) for PMI testing which offers fast, reliable positive material identification that ensures the integrity of your systems across the process plant.

Gasket University

For many years, Masterpac has offered knowledge sharing program called “Gasket University” bringing the most updated information in sealing technology to our customers throughout Kingdom of Thailand and ASEAN countries. This training program designed for every candidates range from mechanical fitters, graduate engineers, to buyers for knowledge sharing about gasket and sealing technology.

Key principles in competence :

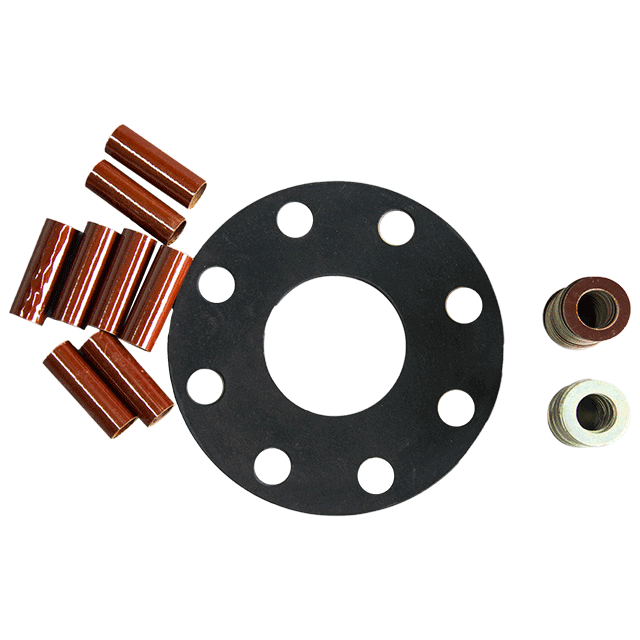

Principles of joint component sealing action

Function of gasket or seal types

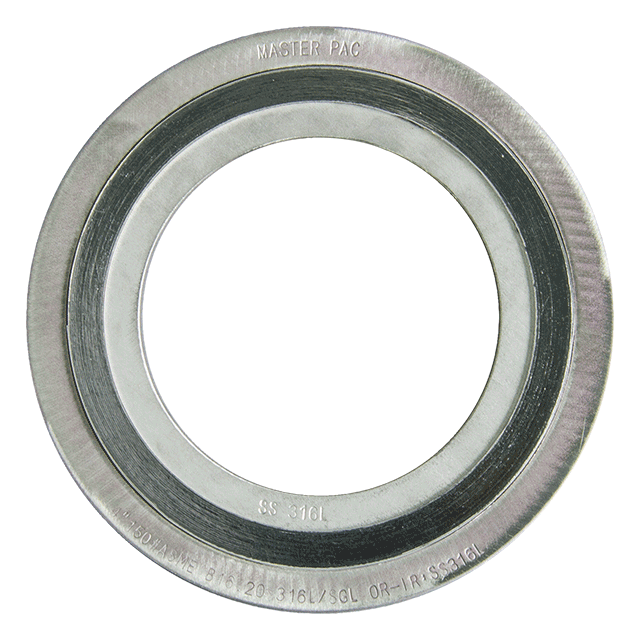

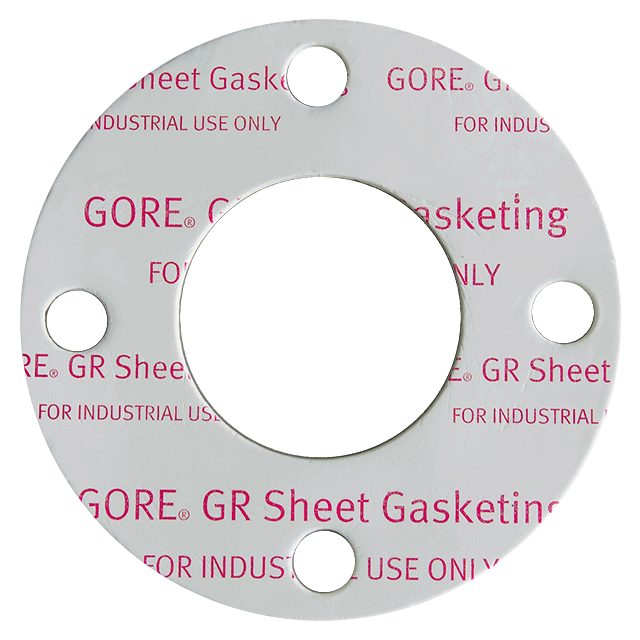

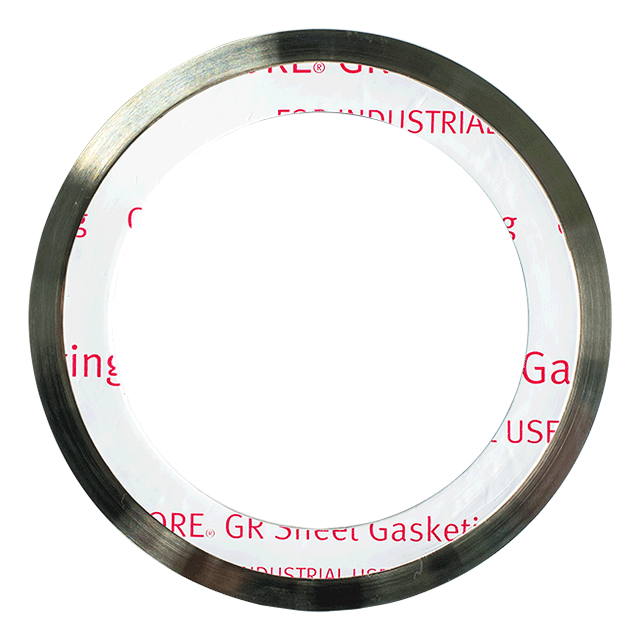

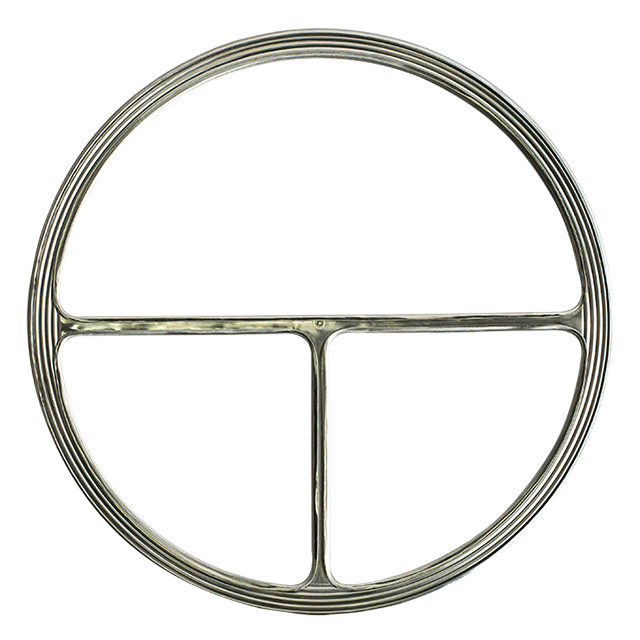

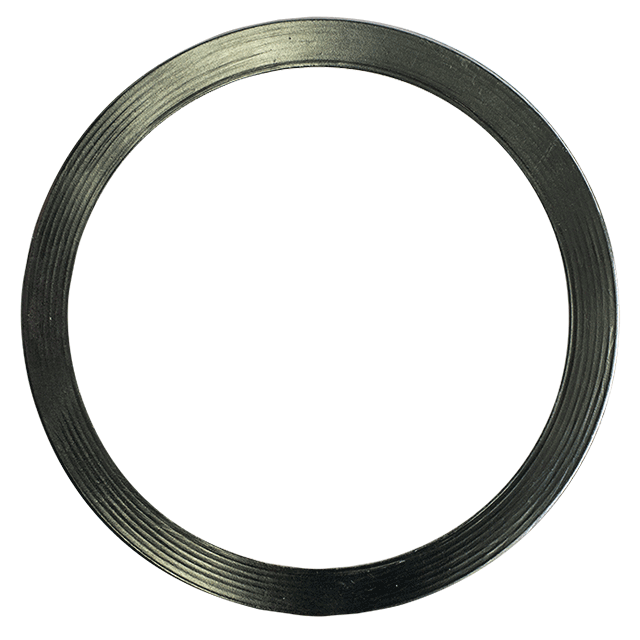

Metallic gasket & semi-metallic gasket

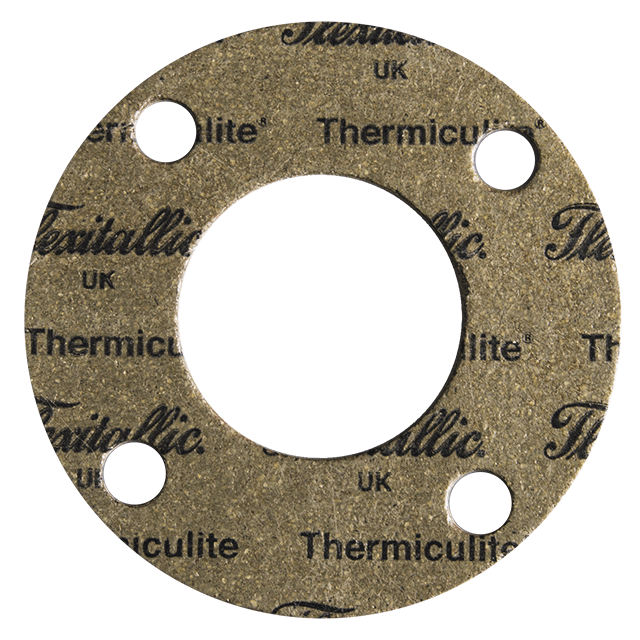

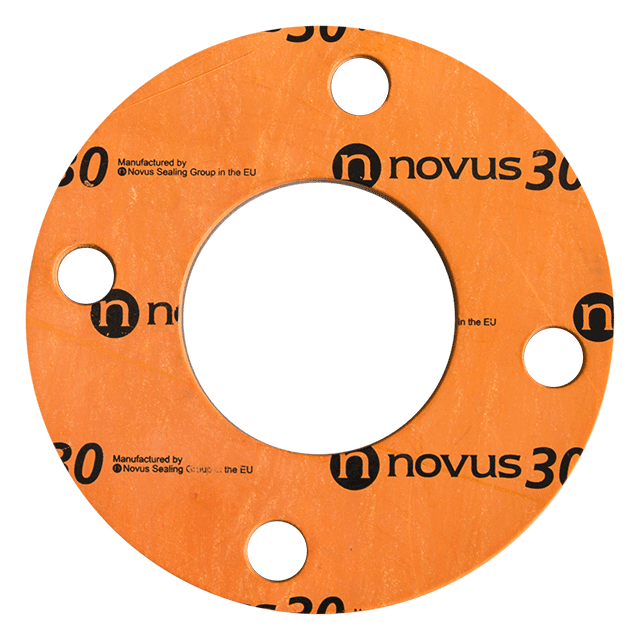

Non-metallic gasket

Pump & valve packing

Gasket selection

Basic bolting techniques & basic gasket installation techniques

Assessment and certification