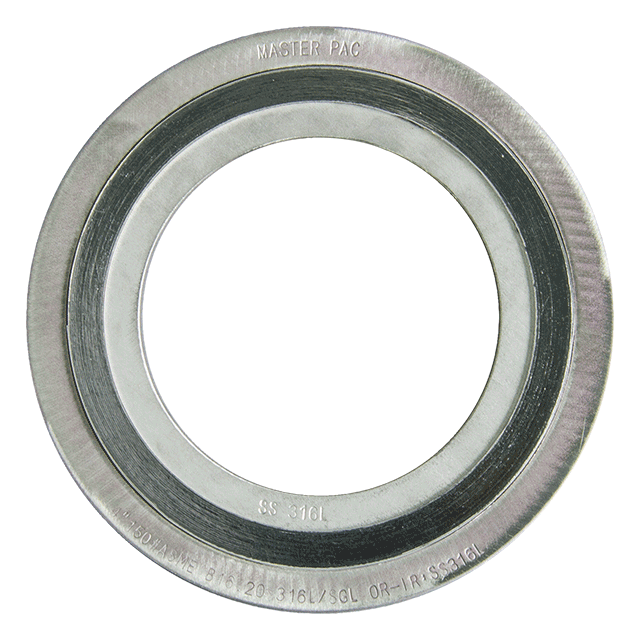

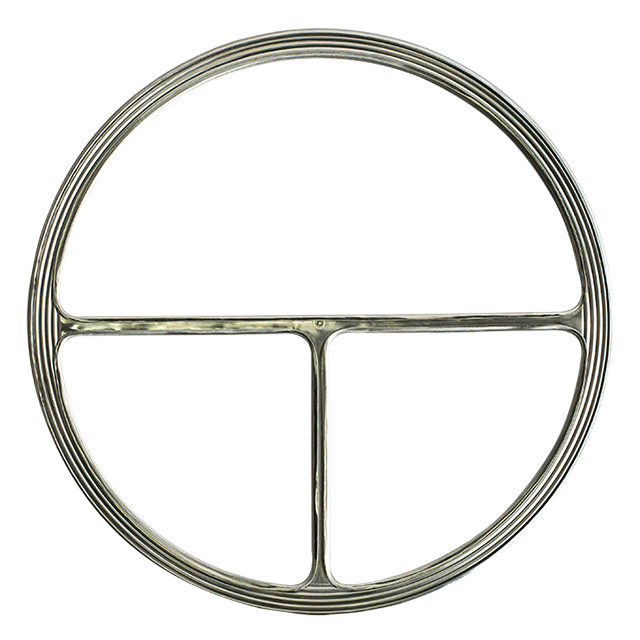

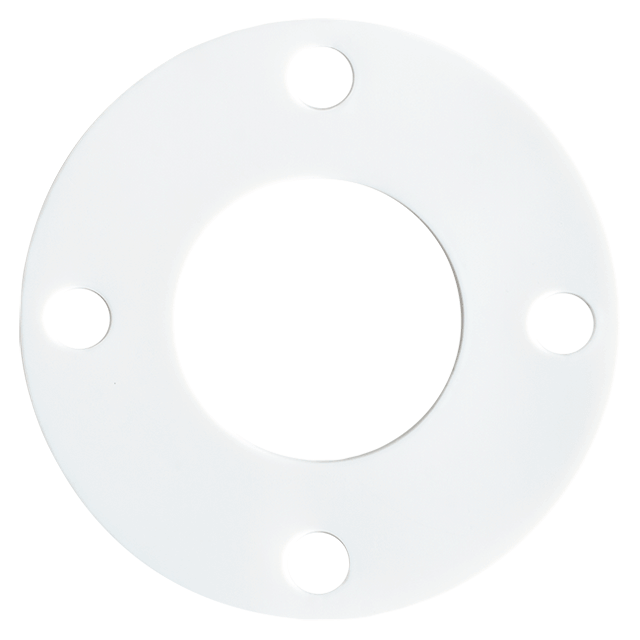

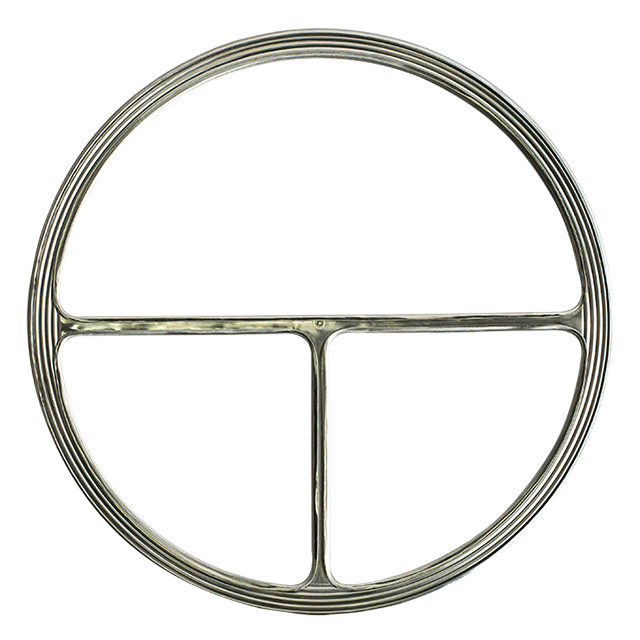

This standard Single Jacketed Gasket has one of its contact surfaces covered and is ideally suited for comparatively narrow flange widths in circular and non-circular configurations but it is not recommended for standard pipe flanges.

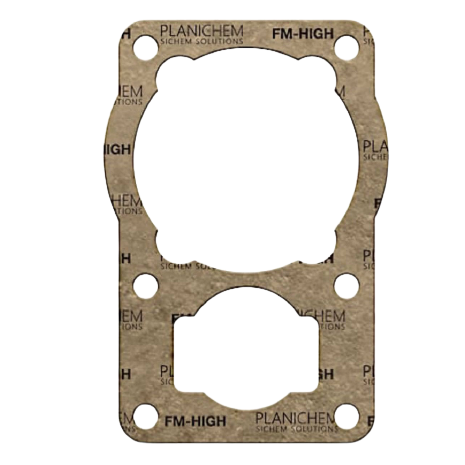

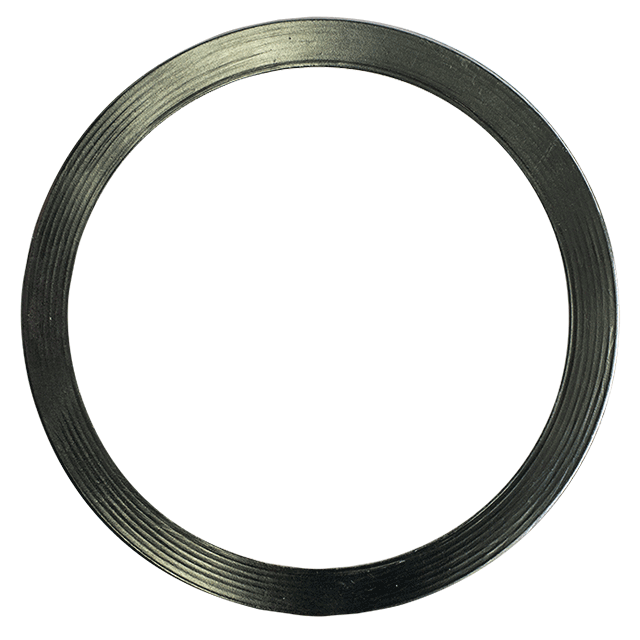

For Overlapped Single Jacketed Gasket, its construction of this gasket offers more filler protection than the standard single jacketed design. It is especially suitable for high temperature applications of narrow gasket widths. Typical low pressure applications include boilers, compressors, pumps, and diesel and gasoline engines.