-

Products

- Planichem MICATHERM®

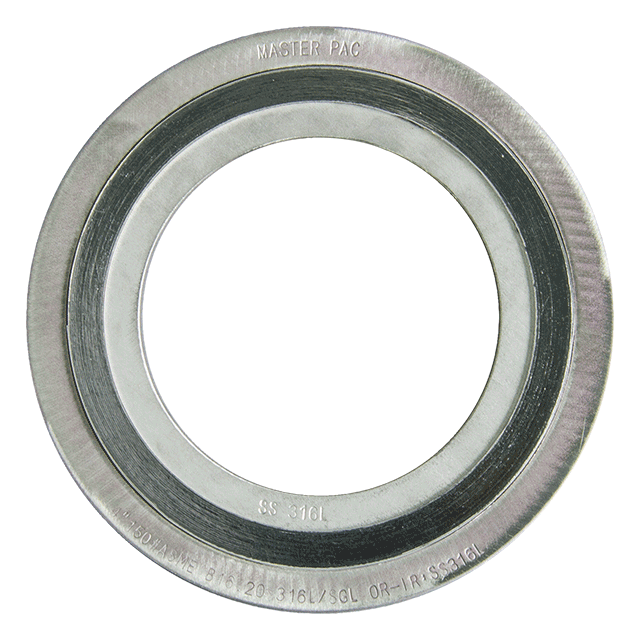

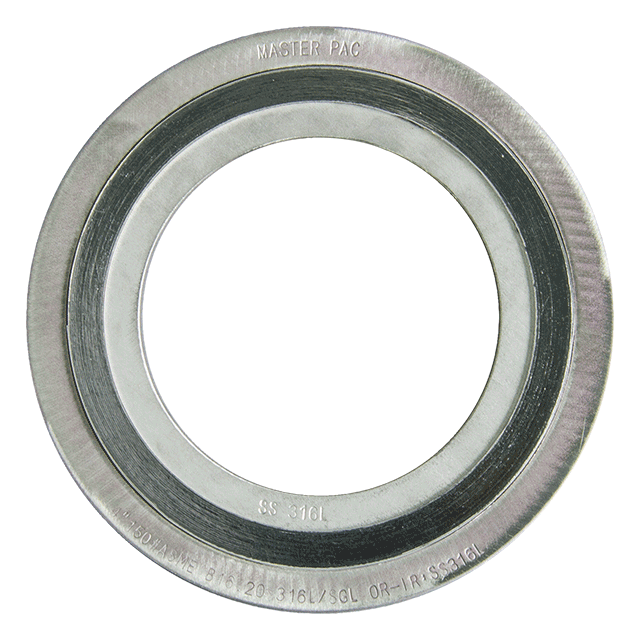

- Spiral Wound Gaskets

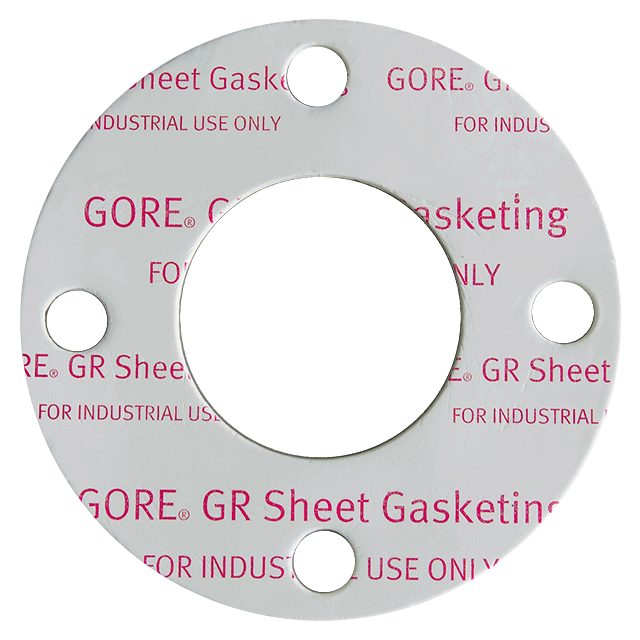

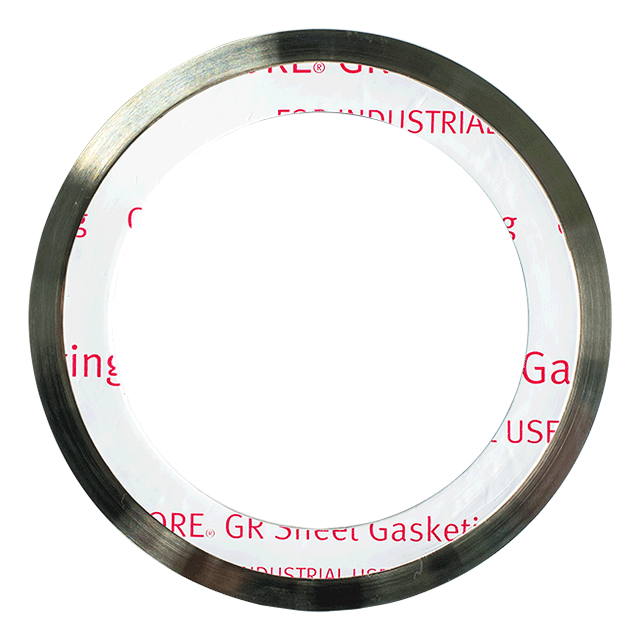

- GORE® Expanded PTFE

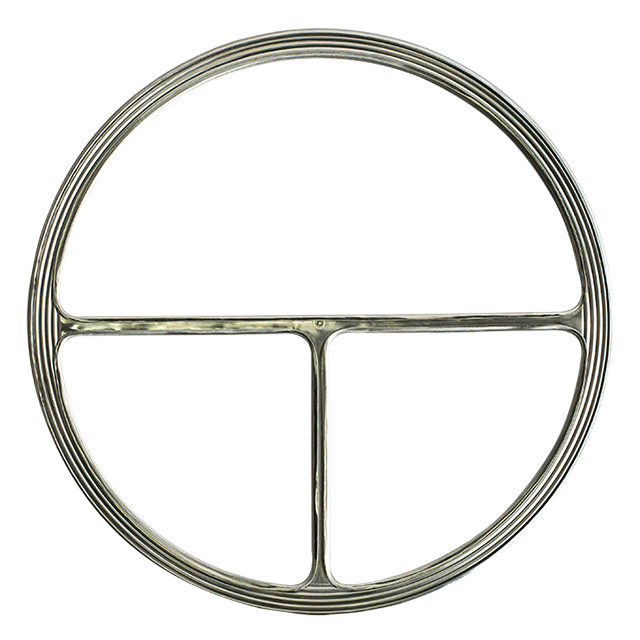

- Camprofile Gaskets

- SIGRAFLEX® Graphite

- Metal Jacketed Gaskets

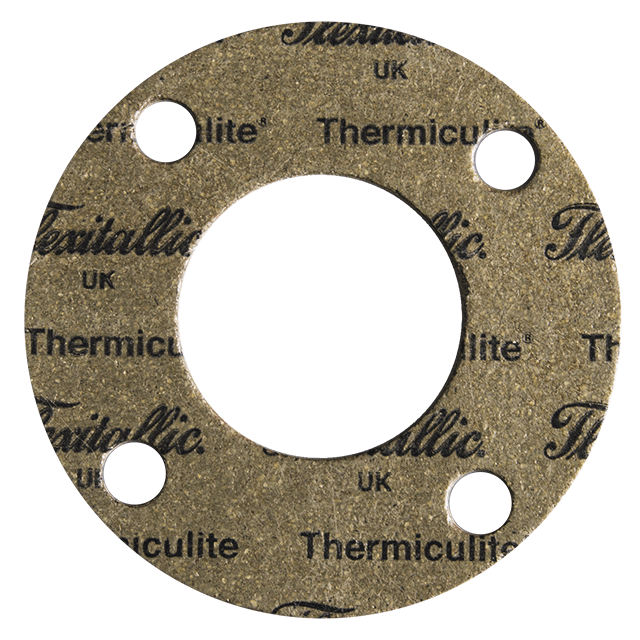

- Flexitallic Thermiculite

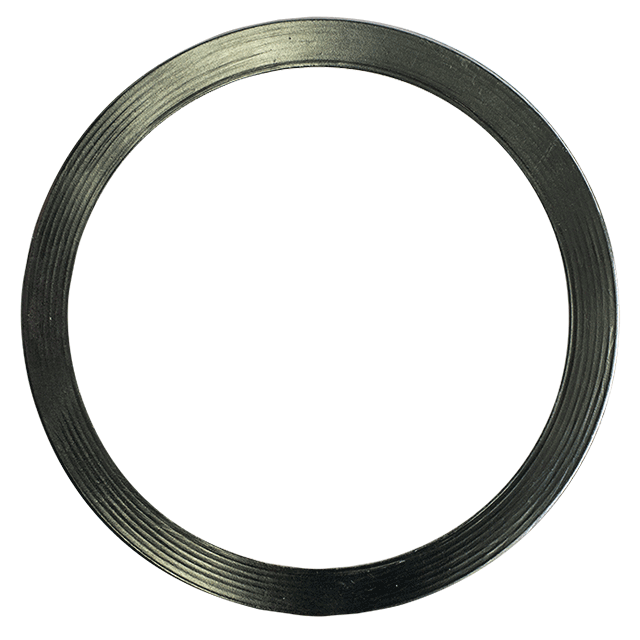

- Corrugated Metal Gaskets

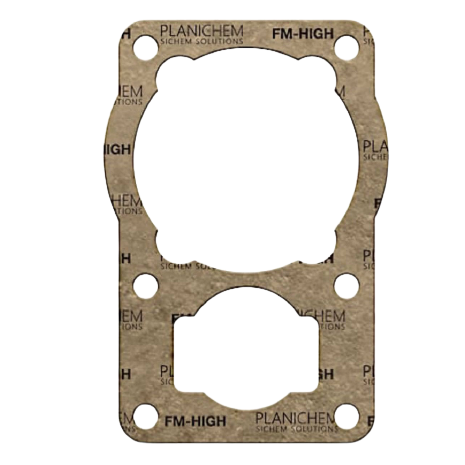

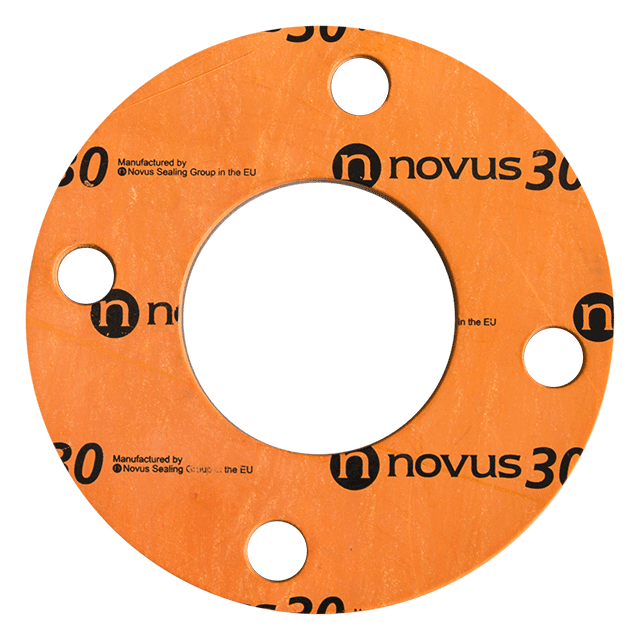

- Compressed Fibre Sheet

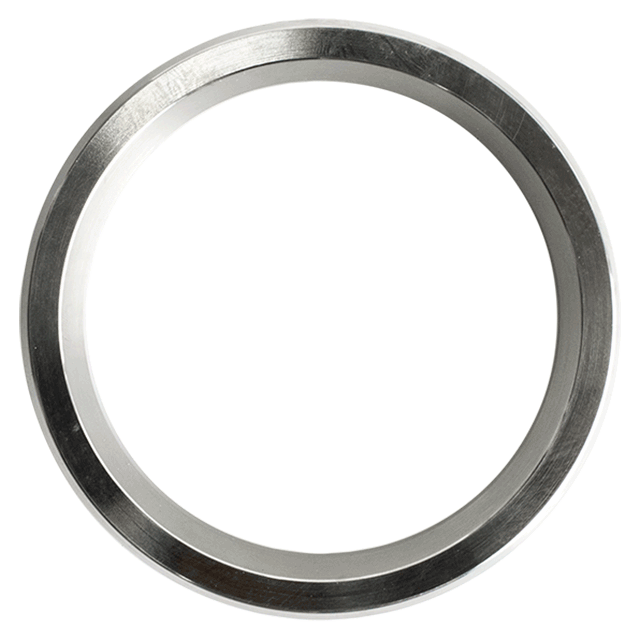

- Ring Type Joints (RTJ)

- Restructured PTFE Sheet

- Compression Packings

- FLEXOID® Gasket Paper

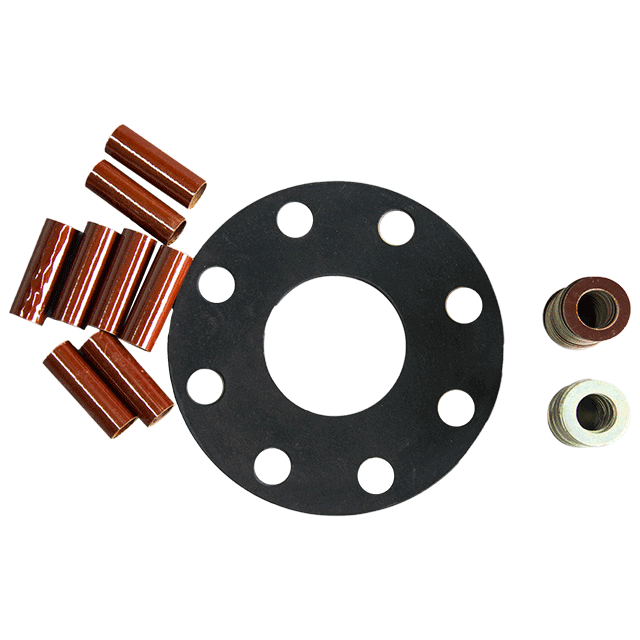

- Isolation Kits

- PTFE Range

- Insulating Textiles

- Graphite Range

- MRO Products

- Elastomer Seals

- SSHE Specialties

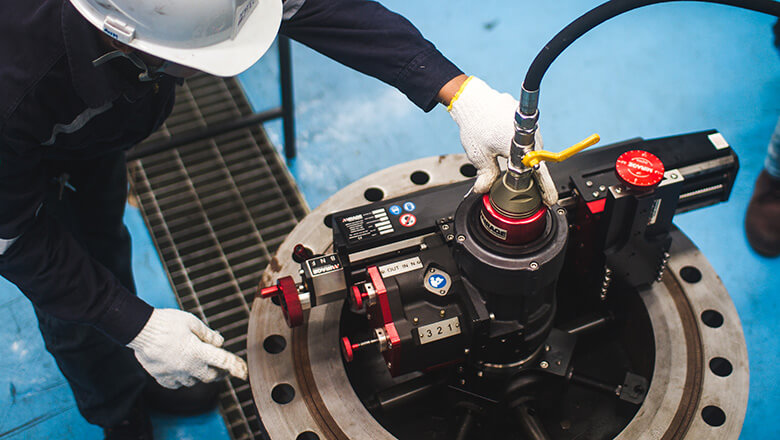

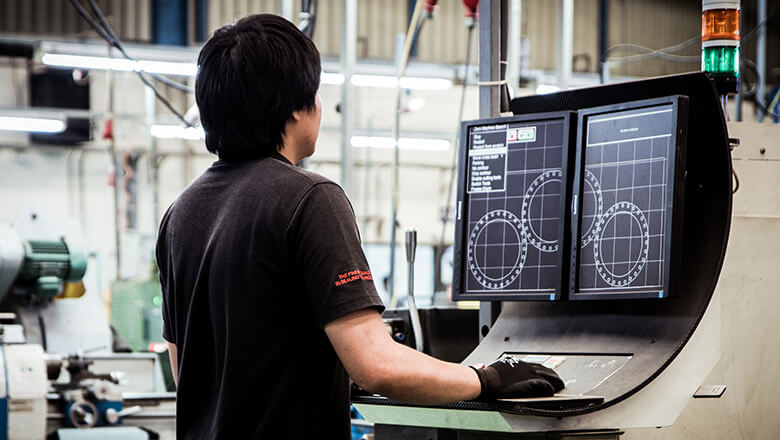

- Services

- Resources

- Company

- Contact Us